Regional Focus

Operating in 22 countries allows us the ability to secure the right global supply partnerships. In turn, it allows for more flexibility at providing the right products and expertise when and where needed — ensuring a higher level of dedicated service.

Maximize Performance, Minimize Cost

Constant innovation drives us forward, which also tends to drive down costs. With one of the most comprehensive chemical product lines in the industry, we also offer in-house laboratory testing capabilities conducted by highly experienced technical personnel.

Innovation Top to Bottom

Chemical innovation for oil and gas partners is our daily driving force. We assess our clients’ challenges, evaluate their goals, then test and recommend the best possible chemical treatment to ensure their success.

Our Success is Measured by Yours

Research and technology. Innospec has invested heavily into developing an extensive R&T group that extends from Ellesmere Port, UK to throughout our full-service regional labs. Even the company name, Innospec, is derived from Innovative Specialty Chemicals – it is this innovative spirit that is the key to our customers’ success.

From Molecule to Market: Chemistry Delivering Real World Application

As oilfield technology advances, the performance gap between water-based muds (WBMs) and oil-based muds (OBMs) has closed. OFS recognized that modern WBMs can deliver the performance of OBMs with significant cost and environmental advantages. An effective drilling fluids must have good pumpability — lower viscosity at higher shear rates for efficient pumping and higher viscosity at low shear rates to suspend cuttings and ensure safe trips. With these principles in mind, OFS introduced two high performance WBM systems: Redi-Guard™, AphronICS™ , and Maxwell™.

Redi-Guard™

Redi-Guard is an environmentally friendly, non-damaging, next-generation drilling fluid additive for a wide variety of drilling and completion applications. When used in fresh water or various brines, Redi-Guard forms the basis of a high-performance WBM. Its unique chemistry provides a highly shear-thinning fluid with exceptional fluid loss control and shale encapsulation. Redi-Guard™ significantly improves hole cleaning, ECD management, and borehole stability while optimizing reservoir protection.

- Efficient: An easy-to-use, multifunctional product that provides superior clay and shale inhibition, outstanding rheology, and fluid loss control.

- Environmentally Friendly: Approved for use in public/drinking water installations (Water Supply Regulations), CEFAS and PLONOR registered, non-toxic, and biodegradable.

- Borehole Stability: Delivers exceptional borehole stability and hole cleaning, greatly enhancing rates of penetration (ROP).

Cost-Effective: Minimizes disposal costs and provides impressive reservoir protection for enhanced production, consistently saving customers time and money. - Superior Results: A proven track record of record-breaking performance with repeatable, predictable, and outstanding field results.

AphronICS™

AphronICS is a solids-free, water-based drilling fluid system that incorporates microbubbles under pneumatic pressure for invasion control. It provides high Low-Shear-Rate Viscosity (LSRV), minimal fluid loss, superior hole cleaning, and excellent borehole stability. AphronICS is engineered to control losses in depleted formations, high-porosity sands, and fractured carbonates, as well as to stabilize pressured shales. The fluid is formulated with organic, biodegradable polymers and non-caustic materials, balancing operational efficiency with environmental stewardship.

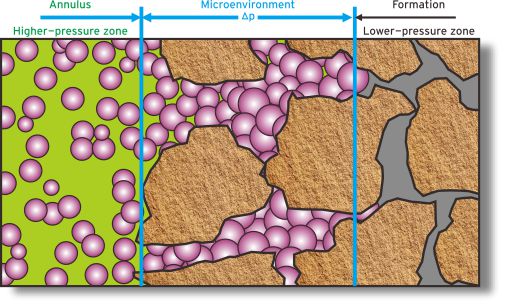

Aphron’s Bridging Mechanism. The bridging mechanism consists of microbubbles that, while encapsulating air, compress during circulation downhole. This action, combined with increasing temperature, energizes the bubbles and increases their internal pressure. When the drill bit exposes a depleted or low-pressure formation, the microbubbles immediately expand and aggregate within the openings, causing external Laplace forces to increase dramatically. This phenomenon raises the internal LSRV and creates a microenvironment that reduces fluid invasion.

Proven Economic Advantages. In hundreds of wells worldwide, operators have seen the economic advantages of the AphronICS system. In many high-angle and horizontal wells, its superior wellbore stability and drilling efficiency have reduced well construction days by as much as 50%. In some cases, intermediate casing strings have been eliminated, resulting in even greater cost savings. The system consistently improves project economics by mitigating drilling problems, delivering highly stable boreholes, simplifying completions, and shortening cleanup times.

MaxWell™ High Performance Water-Based Mud Systems

The industry’s new non-xanthan water-based drilling mud that offers major cost and performance advantages over both oil-based and standard HPWBM systems. MaxWell has been proven to resist oilfield contaminants and is superior to oil-based systems in safety and environmental impact. Additional MaxWell advantages include an outstanding coefficient of friction, higher ROPs, reduced rig time, reduced formation impairment, and improved production and wellbore stability.

MaxWell is also the only polymer product on the market that can build its own solids-free filter cake—one that is not permanent or expensive to clean up. Forming a tight, effective micro membrane across the formation, the MaxWell filter cake acts like a screen to effectively stabilize and protect the formation, preventing drilled solids from being picked up and carried through into the formation.

StrataFlex® Elastomeric Sealant

Strata -Flex. A proprietary, precisely graded, inert elastomeric sealant developed to improve wellbore stability. Its strong seal can withstand higher differential pressures while bridging microfractures and sealing permeable sands. It is highly compressible and deformable, with high tensile and shear strengths that outperform common carbon graphite materials in resilience.

Application: Used as a preventative sweep when loss/seepage zones are anticipated. It improves formation integrity to control seepage in depleted and weak formations, prevents differential sticking, and cures lost circulation. It can seal fractures from 300 to 5,000 µm with fine, medium, and coarse grades.

Benefits:

- Supports filter cake and minimizes fluid invasion in formation

- High resilience and withstands differential pressure.

- High-temperature stability (Melting temperature >1000°F).

Frac-Attack®

Frac-Attack is a proprietary blend designed to provide a complete seal. It is a fast-acting and extremely cost-effective solution for lost circulation in all types of fractures and formations. It is designed for curing severe or complete loss situations by spotting it at or near known loss zones, followed by a hesitation squeeze procedure to de-water the pill and achieve a seal.

Benefits:

- Improves the formation’s integrity, allowing heavier mud weights to be pumped.

- Extremely cost-effective as a complete loss solution.

- No spacers, activators, or retarders required.

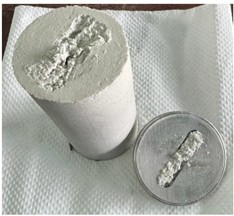

RediSeal™ Squeeze Pill Application

RediSeal is an acid-soluble, high-fluid-loss squeeze pill that provides a high-compressive-strength filter cake. It is designed to cure severe or complete loss situations by spotting it near the loss zone, followed by a hesitation squeeze procedure to form a strong sealing plug. This product is also proven effective in controlling underground crossflows and blowouts. RediSeal can be applied as a background treatment (5-8 lb/bbl) to optimize wellbore strengthening, particularly in reservoir sections.

Benefits:

- A fast-acting, acid-soluble, and reservoir-safe LCM pill.

- Creates a unique filter cake with high compressive strength up to 1,200 psi.

- Improves formation integrity to withstand surge/swab pressures.

HiRate™

Innospec’s Stimulation chemical solutions designed and proven, powerful tools for enhancing the completion design and execution. We pride ourselves on co-developing proprietary stimulation systems to solve complex reservoir problems, lessen formation damage, and reduce unnecessary expense. In addition, we’re adept at replacing chemicals with optimized systems that can help our customers improve their bottom line.

An example is with our friction reducer portfolio, HiRate which are specifically designed with exact science to be more efficient – allowing our customers to use less product to achieve their desired performance results.

In recent years, slickwater fracturing systems depended largely on high performance friction reducers (FR) to achieve the pump rates required for proppant transport and suitable fracture geometry. While simple to use onsite, traditional emulsion-based friction reducers have reached the limits of their performance and affordability.

To overcome the traditional FR limits, our R&D team accepted the challenge to develop an affordable, high efficiency FR that also maintains operational simplicity without need of any special pumping equipment.

HiRate Plus was our first invert polymer emulsion-based FR that provides ultra-fast inversion and hydration, imparting significantly improved friction reduction efficiency.

Easy to mix and meter, the HiRate Plus system— unlike conventional emulsion-based FRs—is based on a higher polymer activity that allows less product per stage; thereby saving operators time and money. If chasing pump rate, the product has a better pressure to rate ratio than the conventional FR’s, allowing higher treating rates.

HiRate MAXX is an invert polymer emulsion-based friction reducer designed for ultra-fast inversion and hydration. This, coupled with higher polymer activity, has repeatedly shown exceptional performance at lower loadings without sacrificing pump rate or designed sand schedules. A better performance to loading ratio enables an array of product attributes to enhance the fracturing treatment.

HiRate MAXX is based on an anionic, high molecular weight polyacrylamide, allowing typical loadings from 0.15 to 0.75 gpt, depending on operator objectives. If lower costs are expected, lower than normal loadings provide lower cost per barrel of treated frac fluid. If the goal is achieving better pump rates, increasing HiRate MAXX loadings to more conventional loadings normally enables 5 to 15 BPM better rate.

VisLink™

For decades, companies have pursued chemical technologies to help maximize production and reduce costs. In the mid 1990s, slickwater fracs were reintroduced as a less expensive, less damaging alternative to conventional crosslinked gel treatments. In the early 2000s, the sequential combination of slickwater and gel (hybrids) was introduced to improve stimulation effectiveness and lower completion costs.

But both technologies have drawbacks – while slickwater treatments provide good fracture development, especially maximizing fracture complexity without causing extensive damage, it suffers from limited proppant carrying capacity, normally less than 2 lb/gal. Furthermore, slickwater’s low viscosity provides minimal fracture width—thereby preventing the placement of high volumes of larger-sized proppant.

In contrast, crosslinked gels offer good fracture development, but poor fracture complexity growth. While this technology does create fracture width for both larger-sized proppant and high volumes of proppant needed for high fracture conductivity, these gels can severely damage the proppant pack, limiting initial and ultimate production.

VisLink 200, the next generation VisLink System offering the best of the viscous gel and slick-water worlds— without the downsides. Like no other solution on the market, VisLink 200 combines the upsides of slick-water and gel systems. Indeed, the visible lipping of the viscoelastic gel is easily observed with gel loadings as low as 8-10 ppt. VisLink 200 cross-linked fluids allow operators to use less chemical while accomplishing the advantages obtained from conventional gel and slick water treatments. The VisLink 200 is designed for improved pumping and cold weather conditions while enhancing the viscoelastic-nature of ultra-low gel systems.

The second generation VisLink crosslinker, VisLink 300. is also a water-based crosslinker that was specifically designed to be more environmentally acceptable and easier to handle. Like the previous generation, VisLink 300 also has an ultra-low loading of guar gum that ranges from 8 to 12 ppt. VisLink 300 functions as a conventional borate crosslinker for higher loadings of guar when necessary, but its mainstay applications are ultra-low loadings of gel.

Suitable viscosity will occur with FANN 35 base gel viscosities as low as 3.5 cP at 511 sec-1. Typical loadings will range from 0.75 to 2.0 gpt with the buffered alkalinity ranging from pH 9.5 to 10.5. Also, any conventional breaker will work with the VisLink 300 crosslinked fluid.

Production Chemicals

Innospec. Where every project begins with 50+ years of product innovation, performance and reliability.

Our production chemical solutions and service offerings integrate more than 50 years of experience and product development into one of the most comprehensive production chemical product lines in the industry. Period.

Production problems occur within the reservoir’s hydrocarbons and water-stream compositions if chemical applications are not regularly monitored and tested. The same holds true if post-production analyses were flawed or chemical treatment programs were poorly designed because of inadequate communications between design engineers, production chemists, and chemical providers.

H2S Scavengers

Hydrogen Sulfide (H2S) is an extremely toxic and corrosive gas. If left untreated the H2S can cause pitting, stress cracking corrosion and iron sulfide deposition, and scaling in producing wells. Not only are high concentrations of H2S extremely dangerous for field personnel, it also prevents operators from selling the hydrocarbon until the H2S is removed. Hence, it is desirable to remove the H2S at the earliest stage possible.

OFS offers a wide range of triazine-based, oil and water-soluble scavengers. These scavengers can be custom formulated to precise needs. In addition, OFS offers non-amine scavengers too.

Midstream

When operational excellence is your only goal, operational excellence is achieved.

Top to bottom, end to end, our midstream pipeline product and services are meant to ensure asset integrity and flow assurance. Our midstream capabilities are also designed to be integrated into a program development and automated chemical management.

As a basic manufacturer, we offer customized solutions for crude and refined products, emphasizing local, personalized service to provide cost-effective treatment programs. Innovative chemical solutions deliver forward thinking program design and implementation. And our industry leading site safety practices and proven solutions ensure reliable performance.

Drag Reducing Agents (DRAs): Improving pipeline productivity while cutting costs.

Simply put, DRAs reduce the frictional pressure within the flow of a pipeline or conduit. Acting as buffers along the pipe wall, drag reducing agents are long-chain hydrocarbon polymers that decrease the amount of energy lost in turbulent formation. DRAs enable operators to increase pipeline flow using the same amount of energy, or to decrease the pressure drop for the same fluid flow rate.

Innospec’s industry-leading DRAs are engineered to solve the complex challenges that other drag reducers fail to effectively, efficiently address.

Suitable for both crude and refined oil applications, OFS DRAs de-bottleneck pipeline systems without expensive equipment upgrades. They also reduce energy consumption by minimizing drag within the pipeline, lower operating pressures without sacrificing pipeline capacity, and prevent additional costs by eliminating both intermediate pump stations and new pipelines from system designs.